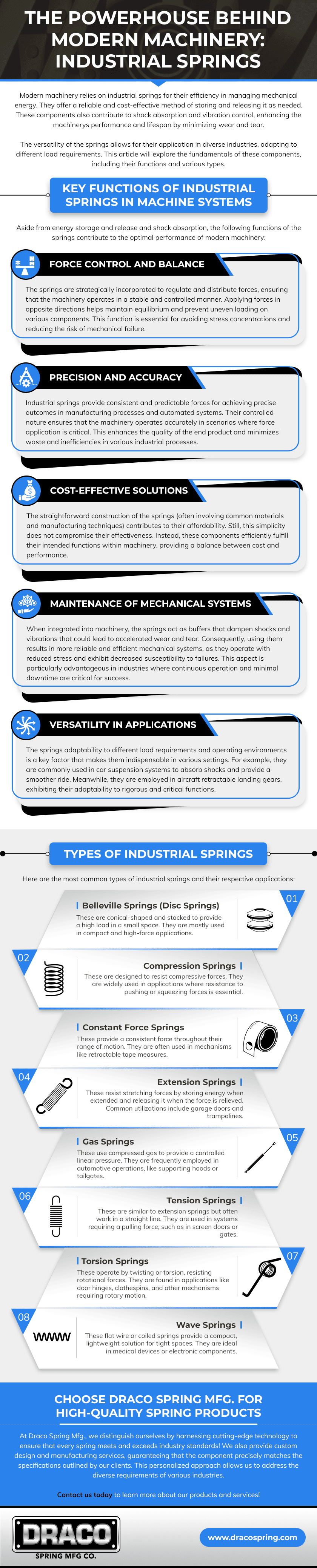

The Powerhouse Behind Modern Machinery: Industrial Springs

Leave a CommentModern machinery relies on industrial springs for their efficiency in managing mechanical energy. They offer a reliable and cost-effective method of storing and releasing it as needed. These components also contribute to shock absorption and vibration control, enhancing the machinerys performance and lifespan by minimizing wear and tear.

The versatility of the springs allows for their application in diverse industries, adapting to different load requirements. This article will explore the fundamentals of these components, including their functions and various types.

Key Functions of Industrial Springs in Machine Systems

Aside from energy storage and release and shock absorption, the following functions of the springs contribute to the optimal performance of modern machinery:

Force Control and Balance

The springs are strategically incorporated to regulate and distribute forces, ensuring that the machinery operates in a stable and controlled manner. Applying forces in opposite directions helps maintain equilibrium and prevent uneven loading on various components. This function is essential for avoiding stress concentrations and reducing the risk of mechanical failure.

Precision and Accuracy

Industrial springs provide consistent and predictable forces for achieving precise outcomes in manufacturing processes and automated systems. Their controlled nature ensures that the machinery operates accurately in scenarios where force application is critical. This enhances the quality of the end product and minimizes waste and inefficiencies in various industrial processes.

Cost-Effective Solutions

The straightforward construction of the springs (often involving common materials and manufacturing techniques) contributes to their affordability. Still, this simplicity does not compromise their effectiveness. Instead, these components efficiently fulfill their intended functions within machinery, providing a balance between cost and performance.

Maintenance of Mechanical Systems

When integrated into machinery, the springs act as buffers that dampen shocks and vibrations that could lead to accelerated wear and tear. Consequently, using them results in more reliable and efficient mechanical systems, as they operate with reduced stress and exhibit decreased susceptibility to failures. This aspect is particularly advantageous in industries where continuous operation and minimal downtime are critical for success.

Versatility in Applications

The springs adaptability to different load requirements and operating environments is a key factor that makes them indispensable in various settings. For example, they are commonly used in car suspension systems to absorb shocks and provide a smoother ride. Meanwhile, they are employed in aircraft retractable landing gears, exhibiting their adaptability to rigorous and critical functions.

Types of Industrial Springs

Here are the most common types of industrial springs and their respective applications:

- Belleville springs (disc springs): These are conical-shaped and stacked to provide a high load in a small space. They are mostly used in compact and high-force applications.

- Compression springs: These are designed to resist compressive forces. They are widely used in applications where resistance to pushing or squeezing forces is essential.

- Constant force springs:These provide a consistent force throughout their range of motion. They are often used in mechanisms like retractable tape measures.

- Extension springs:These resist stretching forces by storing energy when extended and releasing it when the force is relieved. Common utilizations include garage doors and trampolines.

- Gas springs: These use compressed gas to provide a controlled linear pressure. They are frequently employed in automotive operations, like supporting hoods or tailgates.

- Tension springs:These are similar to extension springs but often work in a straight line. They are used in systems requiring a pulling force, such as in screen doors or gates.

- Torsion springs:These operate by twisting or torsion, resisting rotational forces. They are found in applications like door hinges, clothespins, and other mechanisms requiring rotary motion.

- Wave springs: These flat wire or coiled springs provide a compact, lightweight solution for tight spaces. They are ideal in medical devices or electronic components.

Choose Draco Spring Mfg. for High-Quality Spring Products

At Draco Spring Mfg., we distinguish ourselves by harnessing cutting-edge technology to ensure that every spring meets and exceeds industry standards! We also provide custom design and manufacturing services, guaranteeing that the component precisely matches the specifications outlined by our clients. This personalized approach allows us to address the diverse requirements of various industries.

Contact us today to learn more about our products and services!