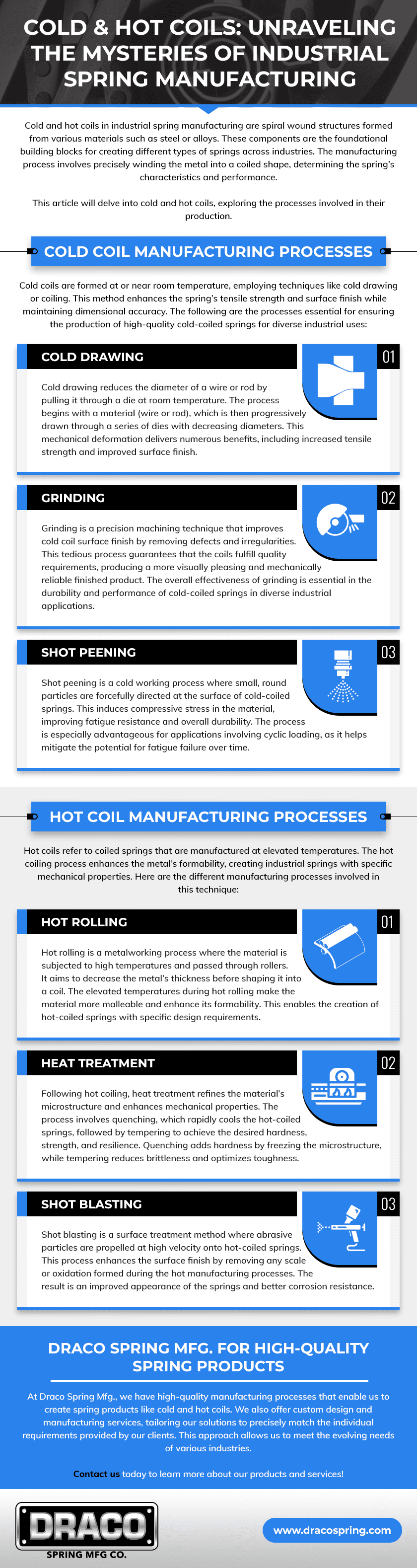

Cold and hot coils in industrial spring manufacturing are spiral wound structures formed from various materials such as steel or alloys. These components are the foundational building blocks for creating different types of springs across industries. The manufacturing process involves precisely winding the metal into a coiled shape, determining the spring’s characteristics and performance.

This article will delve into cold and hot coils, exploring the processes involved in their production.

Cold Coil Manufacturing Processes

Cold coils are formed at or near room temperature, employing techniques like cold drawing or coiling. This method enhances the spring’s tensile strength and surface finish while maintaining dimensional accuracy. The following are the processes essential for ensuring the production of high-quality cold-coiled springs for diverse industrial uses:

Cold Drawing

Cold drawing reduces the diameter of a wire or rod by pulling it through a die at room temperature. The process begins with a material (wire or rod), which is then progressively drawn through a series of dies with decreasing diameters. This mechanical deformation delivers numerous benefits, including increased tensile strength and improved surface finish.

Grinding

Grinding is a precision machining technique that improves cold coil surface finish by removing defects and irregularities. This tedious process guarantees that the coils fulfill quality requirements, producing a more visually pleasing and mechanically reliable finished product. The overall effectiveness of grinding is essential in the durability and performance of cold-coiled springs in diverse industrial applications.

Shot Peening

Shot peening is a cold working process where small, round particles are forcefully directed at the surface of cold-coiled springs. This induces compressive stress in the material, improving fatigue resistance and overall durability. The process is especially advantageous for applications involving cyclic loading, as it helps mitigate the potential for fatigue failure over time.

Hot Coil Manufacturing Processes

Hot coils refer to coiled springs that are manufactured at elevated temperatures. The hot coiling process enhances the metal’s formability, creating industrial springs with specific mechanical properties. Here are the different manufacturing processes involved in this technique:

Hot Rolling

Hot rolling is a metalworking process where the material is subjected to high temperatures and passed through rollers. It aims to decrease the metal’s thickness before shaping it into a coil. The elevated temperatures during hot rolling make the material more malleable and enhance its formability. This enables the creation of hot-coiled springs with specific design requirements.

Heat Treatment

Following hot coiling, heat treatment refines the material’s microstructure and enhances mechanical properties. The process involves quenching, which rapidly cools the hot-coiled springs, followed by tempering to achieve the desired hardness, strength, and resilience. Quenching adds hardness by freezing the microstructure, while tempering reduces brittleness and optimizes toughness.

Shot Blasting

Shot blasting is a surface treatment method where abrasive particles are propelled at high velocity onto hot-coiled springs. This process enhances the surface finish by removing any scale or oxidation formed during the hot manufacturing processes. The result is an improved appearance of the springs and better corrosion resistance.

Draco Spring Mfg. for High-Quality Spring Products

At Draco Spring Mfg., we have high-quality manufacturing processes that enable us to create spring products like cold and hot coils. We also offer custom design and manufacturing services, tailoring our solutions to precisely match the individual requirements provided by our clients. This approach allows us to meet the evolving needs of various industries.

Contact us today to learn more about our products and services!