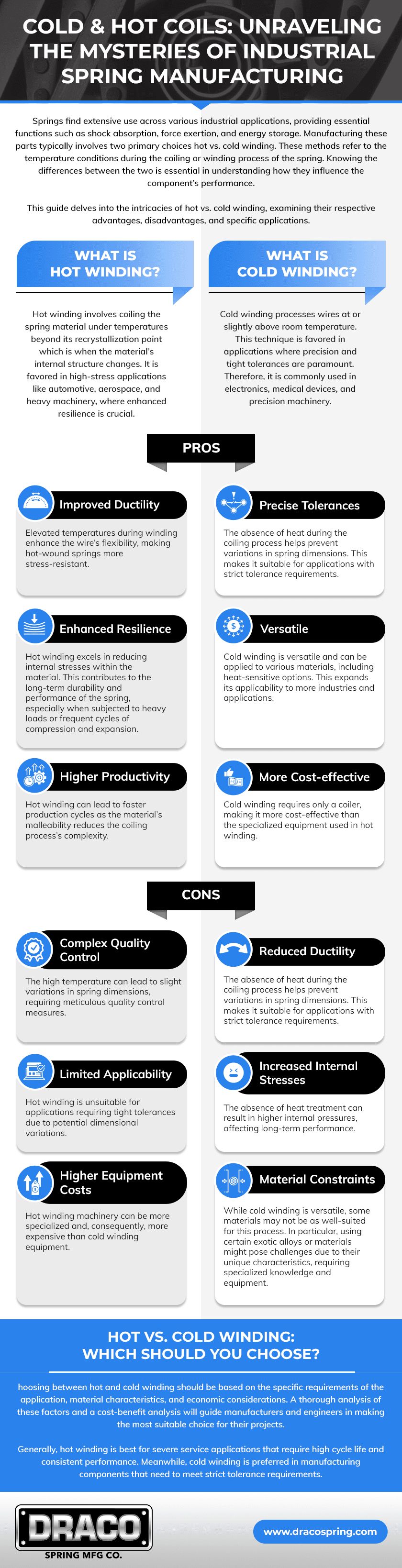

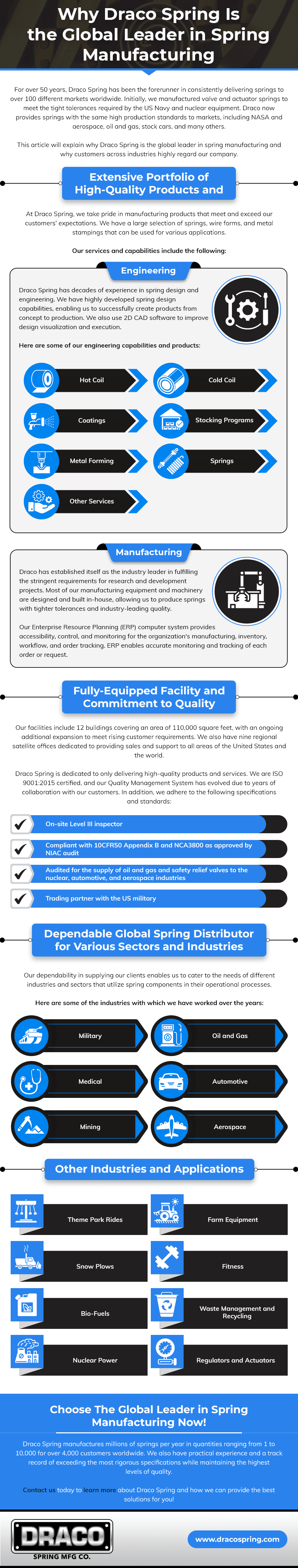

Battle of Techniques: Hot vs. Cold Winding in Spring Production

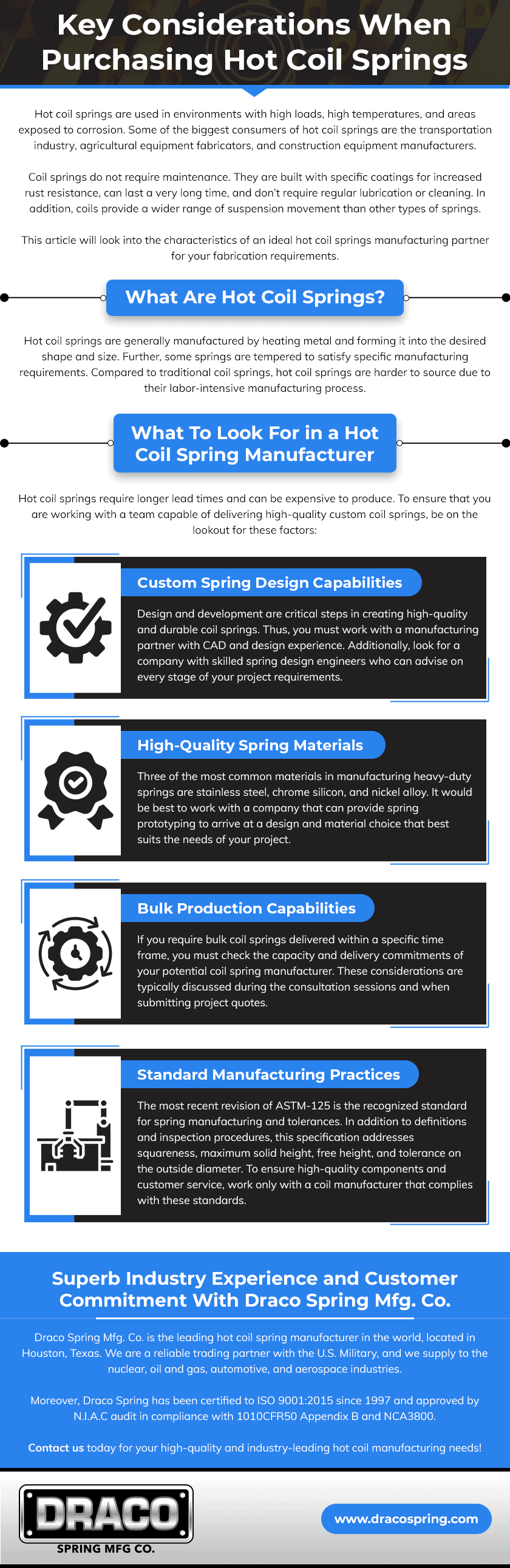

Leave a CommentSprings find extensive use across various industrial applications, providing essential functions such as shock absorption, force exertion, and energy storage. Manufacturing these parts typically involves two primary choices hot vs. cold winding. These methods refer to the temperature conditions during the coiling or winding process of the spring. Knowing the differences between the two is essential in understanding how they influence the component’s performance.

This guide delves into the intricacies of hot vs. cold winding, examining their respective advantages, disadvantages, and specific applications.

What Is Hot Winding?

Hot winding involves coiling the spring material under temperatures beyond its recrystallization point which is when the material’s internal structure changes. It is favored in high-stress applications like automotive, aerospace, and heavy machinery, where enhanced resilience is crucial.

Pros of Hot Winding

Here are the advantages of hot winding:

- Improved ductility: Elevated temperatures during winding enhance the wire’s flexibility, making hot-wound springs more stress-resistant.

- Enhanced resilience: Hot winding excels in reducing internal stresses within the material. This contributes to the long-term durability and performance of the spring, especially when subjected to heavy loads or frequent cycles of compression and expansion.

- Higher productivity: Hot winding can lead to faster production cycles as the material’s malleability reduces the coiling process’s complexity.

Cons of Hot Winding

Despite its numerous advantages, hot winding comes with several challenges, including:

- Complex quality control: The high temperature can lead to slight variations in spring dimensions, requiring meticulous quality control measures.

- Limited applicability: Hot winding is unsuitable for applications requiring tight tolerances due to potential dimensional variations.

- Higher equipment costs: Hot winding machinery can be more specialized and, consequently, more expensive than cold winding equipment.

What Is Cold Winding?

Cold winding processes wires at or slightly above room temperature. This technique is favored in applications where precision and tight tolerances are paramount. Therefore, it is commonly used in electronics, medical devices, and precision machinery.

Pros of Cold Winding

This spring manufacturing technique benefits various industries in the following ways:

- Precise tolerances: The absence of heat during the coiling process helps prevent variations in spring dimensions. This makes it suitable for applications with strict tolerance requirements.

- Versatile: Cold winding is versatile and can be applied to various materials, including heat-sensitive options. This expands its applicability to more industries and applications.

- More cost-effective: Cold winding requires only a coiler, making it more cost-effective than the specialized equipment used in hot winding.

Cons of Cold Winding

Here are the potential drawbacks of the cold winding process:

- Reduced ductility: Cold-wound springs exhibit lower ductility compared to their hot-wound counterparts. This impacts the component’s ability to withstand extreme stress or deformation.

- Increased internal stresses: The absence of heat treatment can result in higher internal pressures, affecting long-term performance.

- Material constraints: While cold winding is versatile, some materials may not be as well-suited for this process. In particular, using certain exotic alloys or materials might pose challenges due to their unique characteristics, requiring specialized knowledge and equipment.

Hot vs. Cold Winding: Which Should You Choose?

Choosing between hot and cold winding should be based on the specific requirements of the application, material characteristics, and economic considerations. A thorough analysis of these factors and a cost-benefit analysis will guide manufacturers and engineers in making the most suitable choice for their projects.

Generally, hot winding is best for severe service applications that require high cycle life and consistent performance. Meanwhile, cold winding is preferred in manufacturing components that need to meet strict tolerance requirements.

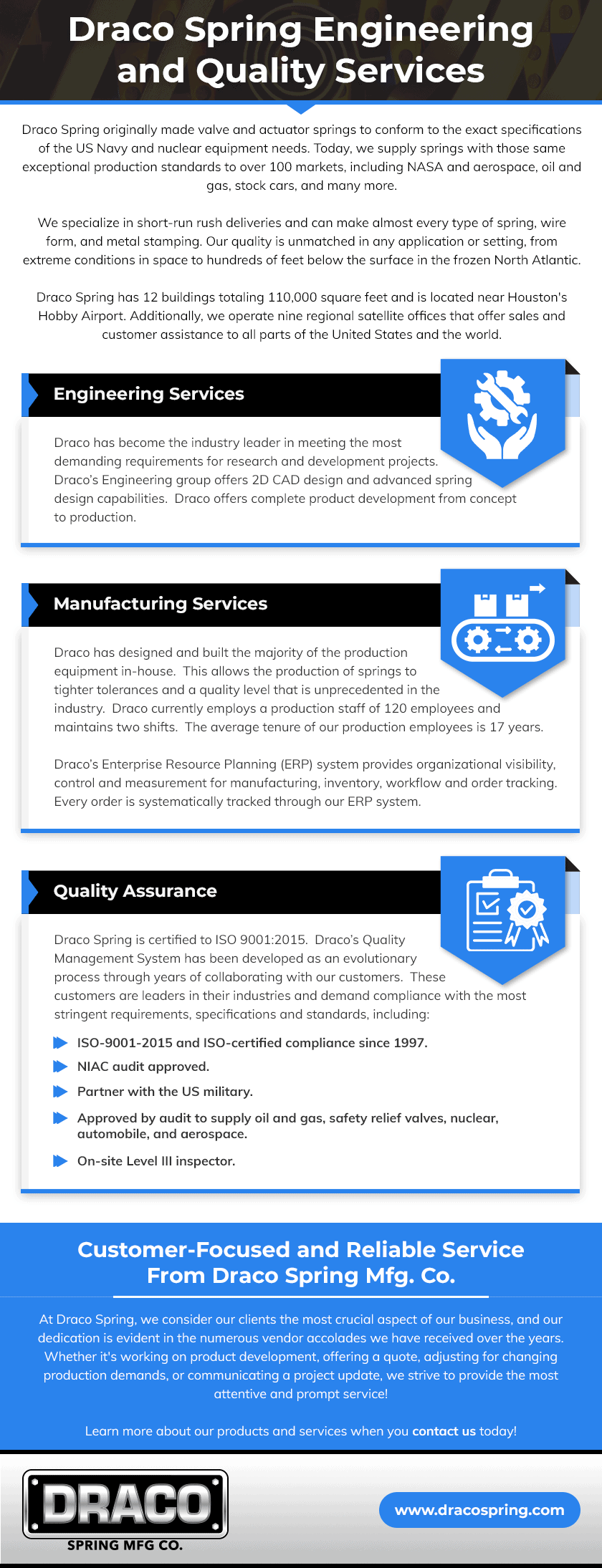

Draco Spring: Your Trusted Source for Quality Spring Components

If you are looking for a reliable partner for your spring manufacturing needs, look no further than Draco Spring! We have been designing and manufacturing top-quality springs to meet the diverse needs of our clients for over five decades. Our state-of-the-art facilities are equipped for hot and cold coiling, working with materials from .006″ to 2.687″ diameter.

Contact us today to discuss your project needs.