Compression springs are utilized in various applications, including vehicle suspensions and industrial machines. They compress when a force is applied and recover to their original shape when released.

With so many compression springs available, determining the best for your needs might take some time. This article will walk you through selecting the best compression springs for your application.

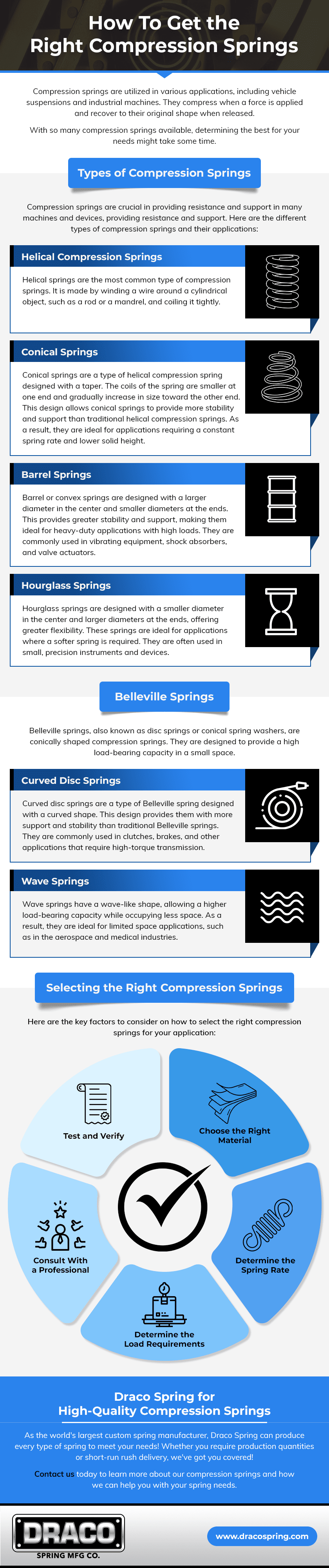

Types of Compression Springs

Compression springs are crucial in providing resistance and support in many machines and devices, providing resistance and support. Here are the different types of compression springs and their applications:

Helical Compression Springs

Helical springs are the most common type of compression springs. It is made by winding a wire around a cylindrical object, such as a rod or a mandrel, and coiling it tightly.

Conical Springs

Conical springs are a type of helical compression spring designed with a taper. The coils of the spring are smaller at one end and gradually increase in size toward the other end. This design allows conical springs to provide more stability and support than traditional helical compression springs. As a result, they are ideal for applications requiring a constant spring rate and lower solid height.

Barrel Springs

Barrel or convex springs are designed with a larger diameter in the center and smaller diameters at the ends. This provides greater stability and support, making them ideal for heavy-duty applications with high loads. They are commonly used in vibrating equipment, shock absorbers, and valve actuators.

Hourglass Springs

Hourglass springs are designed with a smaller diameter in the center and larger diameters at the ends, offering greater flexibility. These springs are ideal for applications where a softer spring is required. They are often used in small, precision instruments and devices.

Belleville Springs

Belleville springs, also known as disc springs or conical spring washers, are conically shaped compression springs. They are designed to provide a high load-bearing capacity in a small space.

Curved Disc Springs

Curved disc springs are a type of Belleville spring designed with a curved shape. This design provides them with more support and stability than traditional Belleville springs. They are commonly used in clutches, brakes, and other applications that require high-torque transmission.

Wave Springs

Wave springs have a wave-like shape, allowing a higher load-bearing capacity while occupying less space. As a result, they are ideal for limited space applications, such as in the aerospace and medical industries.

Selecting the Right Compression Springs

Here are the key factors to consider on how to select the right compression springs for your application:

1. Determine the Load Requirements

The first step in selecting the right compression springs is to determine the load requirements of your application. This will help you choose the strength and size of the compression springs you need. You can calculate the load requirements by using the following formula:

Load = (Force x Distance) / Compression

2. Determine the Spring Rate

The spring rate measures how much force is required to compress the spring by a certain amount. You can calculate the spring rate by using the following formula:

Spring Rate = Load / Compression

3. Choose the Right Material

Some materials, such as stainless steel, are more durable and corrosion-resistant than others. Therefore, you should choose a material appropriate for the environment where the compression springs will be used.

If the springs are used in a corrosive environment, you may need to choose a more corrosion-resistant material. However, if the springs are used in a high-temperature environment, you must select a material that can withstand high temperatures.

4. Consult With a Professional

Consulting a professional is always a good idea if you are unsure which compression springs to choose. They can help you determine the load requirements, spring rate, material, and other factors to ensure that you select the right compression springs.

5. Test and Verify

Once you have selected the compression springs for your application, testing and verifying their performance is important. You should try the springs under the conditions they will be used to ensure they meet the load requirements and provide the necessary resistance.

Draco Spring for High-Quality Compression Springs

As the world’s largest custom spring manufacturer, Draco Spring can produce every type of spring to meet your needs! Whether you require production quantities or short-run rush delivery, we’ve got you covered!

Contact us today to learn more about our compression springs and how we can help you with your spring needs.