Hot coil springs are used in environments with high loads, high temperatures, and areas exposed to corrosion. Some of the biggest consumers of hot coil springs are the transportation industry, agricultural equipment fabricators, and construction equipment manufacturers.

Coil springs do not require maintenance. They are built with specific coatings for increased rust resistance, can last a very long time, and don’t require regular lubrication or cleaning. In addition, coils provide a wider range of suspension movement than other types of springs.

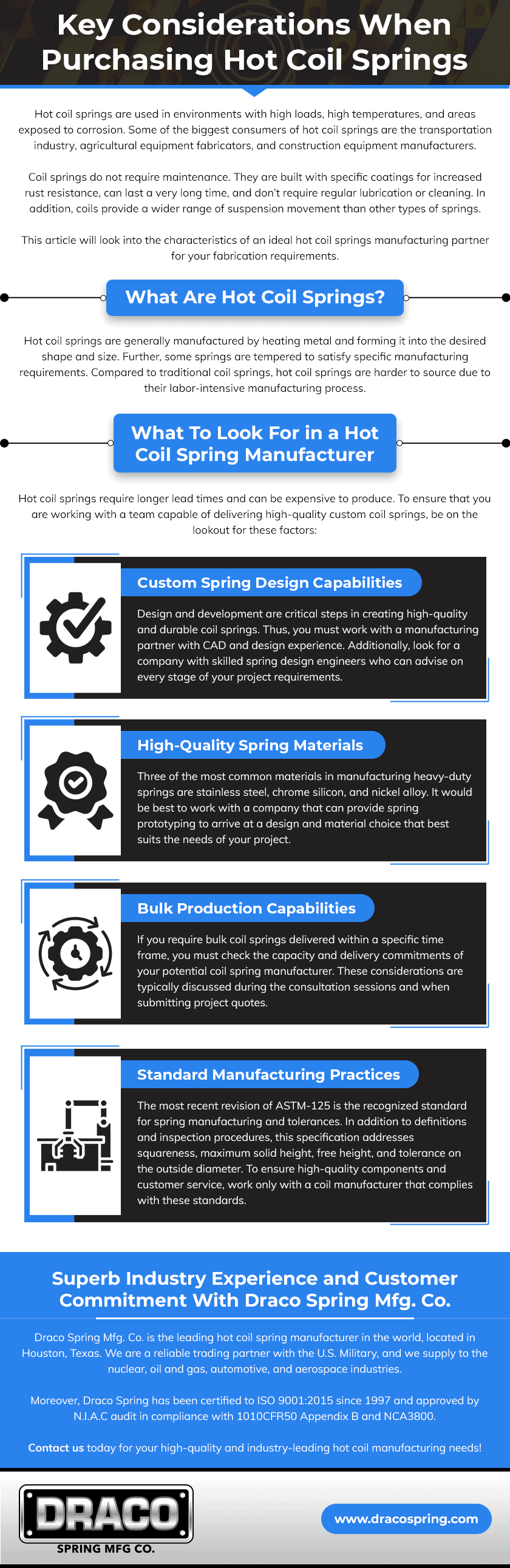

This article will look into the characteristics of an ideal hot coil springs manufacturing partner for your fabrication requirements.

What Are Hot Coil Springs?

Hot coil springs are generally manufactured by heating metal and forming it into the desired shape and size. Further, some springs are tempered to satisfy specific manufacturing requirements. Compared to traditional coil springs, hot coil springs are harder to source due to their labor-intensive manufacturing process.

What To Look For in a Hot Coil Spring Manufacturer

Hot coil springs require longer lead times and can be expensive to produce. To ensure that you are working with a team capable of delivering high-quality custom coil springs, be on the lookout for these factors:

Custom Spring Design Capabilities

Design and development are critical steps in creating high-quality and durable coil springs. Thus, you must work with a manufacturing partner with CAD and design experience. Additionally, look for a company with skilled spring design engineers who can advise on every stage of your project requirements.

High-Quality Spring Materials

Three of the most common materials in manufacturing heavy-duty springs are stainless steel, chrome silicon, and nickel alloy. It would be best to work with a company that can provide spring prototyping to arrive at a design and material choice that best suits the needs of your project.

Bulk Production Capabilities

If you require bulk coil springs delivered within a specific time frame, you must check the capacity and delivery commitments of your potential coil spring manufacturer. These considerations are typically discussed during the consultation sessions and when submitting project quotes.

Standard Manufacturing Practices

The most recent revision of ASTM-125 is the recognized standard for spring manufacturing and tolerances. In addition to definitions and inspection procedures, this specification addresses squareness, maximum solid height, free height, and tolerance on the outside diameter. To ensure high-quality components and customer service, work only with a coil manufacturer that complies with these standards.

Superb Industry Experience and Customer Commitment With Draco Spring Mfg. Co.

Draco Spring Mfg. Co. is the leading hot coil spring manufacturer in the world, located in Houston, Texas. We are a reliable trading partner with the U.S. Military, and we supply to the nuclear, oil and gas, automotive, and aerospace industries.

Moreover, Draco Spring has been certified to ISO 9001:2015 since 1997 and approved by N.I.A.C audit in compliance with 1010CFR50 Appendix B and NCA3800.

Contact us today for your high-quality and industry-leading hot coil manufacturing needs!