For over 50 years, Draco Spring has been the forerunner in consistently delivering springs to over 100 different markets worldwide. Initially, we manufactured valve and actuator springs to meet the tight tolerances required by the US Navy and nuclear equipment. Draco now provides springs with the same high production standards to markets, including NASA and aerospace, oil and gas, stock cars, and many others.

This article will explain why Draco Spring is the global leader in spring manufacturing and why customers across industries highly regard our company.

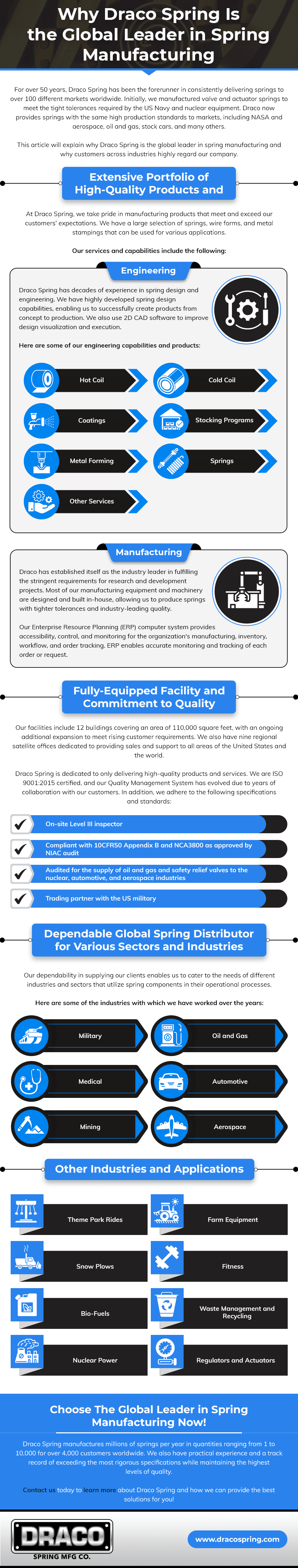

Extensive Portfolio of High-Quality Products and Services

At Draco Spring, we take pride in manufacturing products that meet and exceed our customers’ expectations. We have a large selection of springs, wire forms, and metal stampings that can be used for various applications. Our services and capabilities include the following:

Engineering

Draco Spring has decades of experience in spring design and engineering. We have highly developed spring design capabilities, enabling us to successfully create products from concept to production. We also use 2D CAD software to improve design visualization and execution.

Here are some of our engineering capabilities and products:

- Hot coil: Draco can manufacture hot coil springs up to 2.75 inches in diameter and up to 45 ft. in length. We can also work with almost any diameter spring in a wide range of materials.

- Cold coil: We can manufacture cold coil springs up to 1.75 in. diameter from various stainless and exotic alloys.

- Coatings: Our coating options include paint, powder coat, Thermadep, nickel and cadmium plating, Tectyl, Sermagard, and Xylan.

- Stocking programs: We have vast inventory space for annual blanket orders.

- Metal forming: We produce a wide assortment of metal forms, including sway bars, eye bolts, football sled springs, elevator C springs, snap rings, wire forms, metal stampings, and spring clips.

- Springs: We manufacture all types of springs including compression, pigtail, extension, torsion, tapered, clock, garter, volute, and leaf.

- Other services: We offer additional services such as centerless grinding, parkerizing, Magnaflux, shot peen, liquid penetrant, and load testing.

Manufacturing

Draco has established itself as the industry leader in fulfilling the stringent requirements for research and development projects. Most of our manufacturing equipment and machinery are designed and built in-house, allowing us to produce springs with tighter tolerances and industry-leading quality.

Our Enterprise Resource Planning (ERP) computer system provides accessibility, control, and monitoring for the organization’s manufacturing, inventory, workflow, and order tracking. ERP enables accurate monitoring and tracking of each order or request.

Fully-Equipped Facility and Commitment to Quality

Our facilities include 12 buildings covering an area of 110,000 square feet, with an ongoing additional expansion to meet rising customer requirements. We also have nine regional satellite offices dedicated to providing sales and support to all areas of the United States and the world.

Draco Spring is dedicated to only delivering high-quality products and services. We are ISO 9001:2015 certified, and our Quality Management System has evolved due to years of collaboration with our customers. In addition, we adhere to the following specifications and standards:

- On-site Level III inspector

- Compliant with 10CFR50 Appendix B and NCA3800 as approved by NIAC audit

- Audited for the supply of oil and gas and safety relief valves to the nuclear, automotive, and aerospace industries

- Trading partner with the US military

Dependable Global Spring Distributor for Various Sectors and Industries

Our dependability in supplying our clients enables us to cater to the needs of different industries and sectors that utilize spring components in their operational processes. Here are some of the industries with which we have worked over the years:

Military

Draco Spring provides exceptional products and services to the military industry, particularly for manufacturing, repairing, and maintaining jet aircraft, tanks, ships, submarines, armored vehicles, and missile guidance.

Oil and Gas

We have experience creating custom-made spring components for valves, actuators, downhole tools, drilling equipment, seismic devices, and nitrogen service units in the oil and gas industry.

Medical

Springs are used in nearly all critical medical equipment components, allowing for better and longer-lasting devices. Mainly, they are used as shock absorbers and force generators in medical instruments such as inhalers, EpiPens, bandaging devices, and monitoring systems.

Automotive

Different spring types are widely used in the automotive industry because they play critical roles in a vehicle’s suspension system. They are also applied to clutches, brakes, and transmissions.

Mining

The mining industry uses spring parts and components in vibratory shakers, heavy equipment, water blasting, earth-moving devices, and rock crushers.

Aerospace

Springs serve as the base for many parts and components, allowing aerospace devices and equipment to function as they do. These include drones, satellites, solar panels, aircraft controls, valves, and throttles.

Other Industries and Applications

- Theme park rides

- Farm equipment

- Snow plows

- Fitness

- Bio-fuels

- Waste management and recycling

- Nuclear power

- Regulators and actuators

Choose The Global Leader in Spring Manufacturing Now!

Draco Spring manufactures millions of springs per year in quantities ranging from 1 to 10,000 for over 4,000 customers worldwide. We also have practical experience and a track record of exceeding the most rigorous specifications while maintaining the highest levels of quality.

Contact us today to learn more about Draco Spring and how we can provide the best solutions for you!